Numerous farmers are in search of solutions to decrease the emission Ammonia and other fly problems which are caused due to the layer operation they carry out. Many others are searching out for options to earn money by selling litter as a Chicken litter fertilzer. Chicken litter as fertilizer has some of its distinct benefits which are not found in other commercial fertilizers. VDL Agrotech has brought advantages to both the groups of farmers by devising a system for the purpose of drying of Poultry manure. It is important to carry out composting of Chicken litter because fresh manure should not be used as it contains different Bacteria. Chicken litter compost takes about 2 to 3 weeks before its ready. According toWiebe Van Der Sluis, Rooster45, Doetinchem, the Poultry litter of the Netherlands can prove a nuisance, and especially when they are not handled well or are left on some pile within or outside the poultry house. It emits high levels or concentrations of Ammonia in the environment and makes it unhealthy for birds, workers and the surrounding neighbors. Government also prohibits such emission of Ammonia into the atmosphere as it damages the environmental conditions. So proper litter management in Poultry is essential for preventing risks to both human and bird’s health.

Such a place becomes suitable for the growth of wet litter flies and their population increases in large numbers which is not liked by both farm workers and the neighbors. Therefore both large and medium scale producers of poultry are now showing keen interest in keeping the Poultry droppings dry whether they are in a poultry house or outside it. Majority of the housing systems of poultry provide means to drying out the droppings or Poultry Waste within the house at manure belt. However, the capacity of such Poultry waste management systems is a limited one and gives rise to large proportions of dust which is the reason why farmers normally opt for drying manure outside of the poultry or fowl house. The Fowl manure is transferred by farmers on daily basis or after two days in order to cut down on the emission of ammonia and dust production and to cut on the moisture which is produced in the house. Drying of manure in an environment which is specifically conditioned to capture dust and ammonia will call for lesser energy consumption.

Using steel plates to dry manure

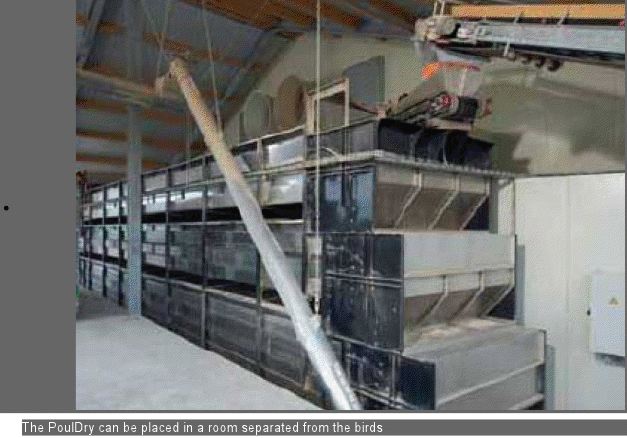

Many systems are present in the market for drying out manure but they have their own features and drawbacks. VDL Agrotech Company which has rendered numerous installation of large and small scale projects of poultry have devised a new Poultry management system of manure drying and they have named the system as ‘PoulDry’. The manufacturing of this effective drying system from Agrotech is the result of cooperation of various experienced engineers who have also been behind the development of various other drying systems. A separate location close to the poultry house is normally chosen to place PoulDry system. The system comprises of one, two or more levels which are linked to direct chain that revolves around powder coated and galvanized steel plates. The plate’s compromise of perforations which keeps almost 35 percent of the systems surface open and this allows air to pop in easily and facilitate fast drying. The system has been designed in such a manner so that no moving part comes in contact with the manure, and this protects them from damage. Similarly the direct chain system driver ensures an easy motion of the drying system.

Forcing of tilt

The droppings in the poultry house which comes via the manure belt are dispersed on the top layer of the drying tunnel which is in circular motion. When the Chook manure is on the edge of the top layer, the perforations on the layers tilt and drop the manure on plates which are at the second level below and this continues its movement to the opposite path via the tunnel so that more moisture can be released. Clogging and sticking of the manure on the plates is prevented by forcing the perforated plates to tilt. High pressure of air is blown throughout the system which results in 80 to 85 percent dryer manure within maximum 72 hours which also depends on the humidity in the atmosphere. The process also causes a reduction in the release of dust particles by almost 70 percent. It has now been learned through experience that the process requires a lesser consumption of energy and can be controlled very easily and effectively via touch screen system. A system with a length up to 40 meters can be installed easily and it has the capacity to dry 200,000 layers of manure. 80 percent drying of manure content which is facilitated through this system reduces fly problems, Ammonia and odor, and such content can be sold easily as field fertilizer. A Poultry management guide should always be consulted for various aspects of poultry such as Chicken litter, manure nutrients analysis etc, and many such guides are available in the market and on the internet.

Karin Jonkers

Marketing Communications Manager

VDL Agrotech

Phonen: : +31(0)40 29 25 577

E-mail: k.jonkers@vdlagrotech.n

Dear Author,

this is a very good informative useful article. Please give me more details about the drying equipment etc to my mail address.

thank you

i have included the detail of supplier in my post.u can check it

Is there any information on the reduction of NH3 and odor?

I hope and wish more could read your poultry guide. It is a great help to people like me in the Philippines. I am wondering where I could buy pairs of breeding poultry nearby Northern Luzon, Philippines.